OVERVIEW

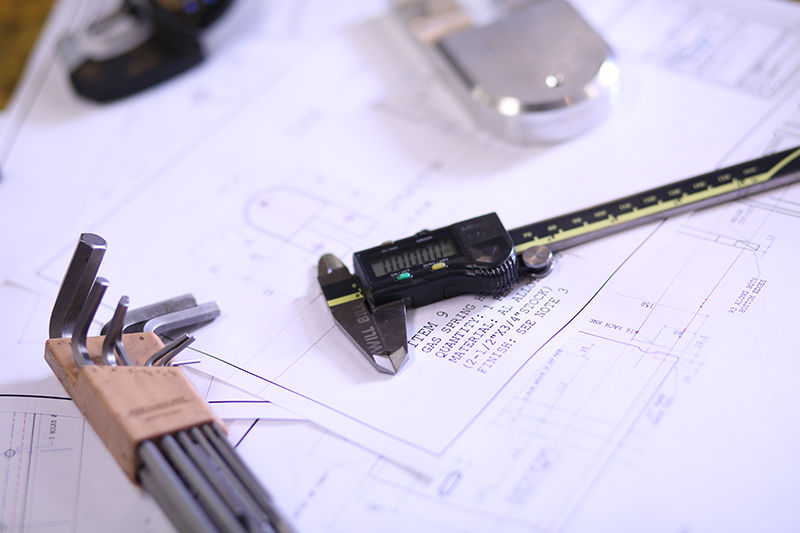

Whatever the requirement, DA can respond quickly. We can work from your ideas or sketches, old or worn components, 2 D drawings through to your fully featured 3D models. We use FARO technology to probe complex shapes, rapidly producing a digital 3D model of your component. Our fully integrated CAD-CAM facility means we can progress from model to finished part quickly and efficiently.

We offer 3D printing in a range of materials where appropriate. All our machinery is programmed offline using EdgeCAM software, dramatically reducing the time taken to program CNC machinery manually. Fewer errors, parts produced quickly, correctly and economically.

TECHNOLOGY

6 Axis Faro Arm 3D probing

Autodesk Inventor 3D & 2D Modelling

3D Printing in a range of plastics

Reverse Engineering

Rapid Prototyping

OUR WORKING METHOD

3D PRINTING

INSPECTION FACILITIES

Trimos Digital height gauge

Shadow Graph